PEC Laser Completes Stainless Steel Ring Project for Houston Gasket Production Company

A large Houston-based gasket production company came to PEC Laser with a challenge. The company had been importing stainless steel rings from a manufacturer in China, but they were waiting anywhere from 6-8 weeks to take delivery. In order to meet their customer demand, they needed a location provider who could provide a faster turnaround time and competitive pricing.

A conventional machine shop would “part-off” the various thicknesses on a lathe. This method can be expensive and time consuming due to the set-up time and cutting tools involved.

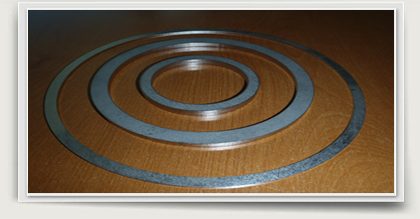

The client showed PEC Laser the desired ring thickness and the various diameters required. Using precision laser metal cutting technology, PEC Laser created prototypes, that matched the prints and they were off and running.

Challenges

However, the PEC Laser solution did not come without challenges. While PEC Laser delivered much faster than the source in China, they ran into challenges associated with laser cutting the rings from flat sheets of stainless steel as opposed to parting-off the rings from tubes.

They also had to ingeniously nest the various ring sizes on the flat metal in order to use as much of the material as possible and minimize waste.

Solutions

PEC Laser nested the rings to properly utilize all material. However, the rings they were making caused some handling issues and delayed the completion process due to the nesting process. PEC Laser utilize micro joints between the metal rings to hold the material in place.

Then PEC Laser finished the rings by tumbling them to break the edges and ultimately achieved the desired finish.

PEC Laser has now established a repeatable process for producing these stainless steel rings that ultimately helps their customer source parts in a more efficient way.

And when you factor in the delivery time, minimal logistics, no need for overseas shipping and importing, the cost to source the Stainless Steel Rings from PEC Laser was reduced.