Valve Manufacturer from the Oil & Gas Industry uses Laser Metal Cutting Solution

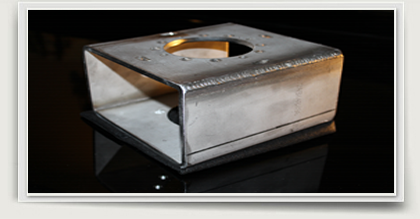

Valve actuator brackets are abundant in the oil & gas industry. They are typically produced by machine shops in the Gulf Coast Region, through the abrasive water jet or plasma metal cutting process or conventional machining. However, the cosmetic appearance is often inadequate using those technologies, since expensive valves are attached to these brackets. Laser metal cutting is more precise and lends to a cleaner edge and a more professional finish.

A large valve manufacturer in Houston hired PEC Laser to produce valve actuator brackets in several thicknesses including

¼”, ¾” and 1” thickness

Challenge

For the 3/4” thick bracket, PEC Laser had to bend a very thick plate. They had the 260 TON Press, but they needed special tools and dies.

Solution

In order to be cost effective, PEC Laser created the necessary tooling from their laser machine, and then used this special tool on the press brake. So rather than spending $10,000 on a special tool, PEC Laser made their own, and significantly reduced the cost of the fabrication method.

There is now a system in place, and the customer is re-ordering the actuator brackets. The solution ended up saving the customer money, created a better long-term solution for repeating this business.

For the brackets that were 1” thick, the metal was just too thick to bend and PEC Laser decided to create two separate pieces and weld them together. This single weld was approved by the customer and all tolerances were still achieved.

The customer is now set up to re-order all brackets and the cosmetic appearance, with the edge quality from the laser machine, has surpassed the customer’s expectations.